Different industries need different packaging equipment. They are built to handle a variety of kinds of products, from heavy to small items, as as delicate components. They are typically constructed using sturdy construction and modern technology to guarantee an efficient and precise packaging.

Food packaging equipment Food packaging equipment is specifically designed to meet strict hygiene and safety requirements. They typically have simple to use surfaces, sophisticated sanitation equipment, temperature control options as well as other features that ensure the safety and the quality of packaged food items.

Cosmetics packaging machine- Cosmetics packaging machines can handle fragile containers such tiny vials or tubes. These machines are equipped with gentle handling systems that ensure that the items are packed with care.

Pharmaceutical packaging equipment They are designed to meet the stringent safety and regulatory needs of the pharmaceutical industry. They are fitted with the latest labeling technology and tamper-evident seals.

Household product packaging machines They are capable of handling a wide assortment of household products, including cleaning products and detergents. They typically have features like multiple-head packaging and flexible configurations for packaging. filling system to ensure that household items are packaged efficiently and efficiently.

In conclusion, packaging machines for various industries differ depending on the particular requirements of each industry, including the size and shape of the product packaging material, size and shape, as well as desired output, and are designed to meet the unique demands and rules of each industry. Read the top rated Contenants de boissons for site recommendations.

What Are The Most Cost-Effective Packaging Solutions That Can Be Used By Industrial Companies?

Small packaging in the industrial sector Automated packaging lines can be used to make small packaging in the industrial industry. Small format sealing machines, vertical form fill sealers, packing machines, and multihead weighers all aid in increasing efficiency and accuracy during the process of packaging. Automated storage management systems can also be used to optimize the storage and retrieval of small packaging.Palletizing for Long Periods- Robotic palletizing systems can be used to improve the efficiency of the palletizing process, while also reducing the risk of injury to operators. These systems can process various types of packaging and are able to be programmed so that they can process pallets at speeds of high speed.

Take care of fragile vials as well as small vials The use of special packaging equipment may be used, such as blister packing machines, to care for fragile vials in the beauty and cosmetics industry. These machines can ensure that vials and containers can be packaged securely and safely with little handling. This reduces the risk of damage.

In all instances, packaging equipment and methods should be chosen based on the product and production process. Be aware of factors such as speed, accuracy, and security. It is also recommended to create a preventative maintenance schedule to ensure that your equipment is able to continue to perform efficiently and effectively over a long duration. Take a look at the top Improved throughput for website examples.

A Selection Of Machines, Systems , And Equipment That Are Suitable For The Food- And Beverage Industries Will Be Discussed.

Blast Chillers- Blast coolers are special refrigeration units that reduce the temperature quickly to prevent the growth harmful bacteria. They are commonly employed in the food and beverage industry to ensure the safety of food products. These methods increase efficiency , while maintaining quality.

Packaging of trays and cardboard Boxes Packaging equipment such as case erectors, tray makers and case erectors could be used to package food products in cardboard boxes or tray. These machines can form the box or tray, then fill the box with the product and then seal it and seal it all in one, automated process.

Shrink Sleeves- Shrink sleeves may be applied to beverage and food containers with shrink sleeves machines. The sleeves are positioned over the containers, and then heated to cause them to shrink and to conform to their form. This results in a beautiful and durable, tamperproof and tamper-proof packaging solution for food and beverages.

When choosing the packaging equipment you choose it is essential to consider the specific requirements of the food or beverage product. This includes the size, shape , and fragility. Packaging equipment must conform to the food safety guidelines (such as those set out by FDA or USDA) to ensure that the products are safe for consume. See the most popular Équipement d’encaissage automatique for more advice.

Wraparound Case Packer Containing Automated Feeds (Including Flatbed Die Magazines)

A wrap-around case-packer is a type packaging machine that wraps boxes around. The machine has adjustable automatic feeds that can handle various dimensions of boxes. The machine comes with the ability to feed boxes to be fed at an even rate. This flexibility makes it ideal for many industries and applications.

The wrap-around case packer is equipped with an adjustable flatbed die magazine that can be adjusted to accommodate various dimensions and shapes of boxes. This makes it possible for the machine to be used for a broad range of packaging applications without the need for massive modifications or tools changes.

Wrap-around cases have a variety of advantages, among them their versatility and ease of use. These features will make sure that the device operates efficiently and precisely even in production environments.

Overall, a wrap-around case packer that has automatic feeds, adjustable flatbed die magazine, and the ability to adapt to a variety of formats is an effective and economical solution for a variety of packaging applications, and it can help to streamline operations and improve productivity in a variety of industrial settings. See the most popular Compact for site advice.

Custom-Designed Packaging Systems For Industrial, Household, And Food Items

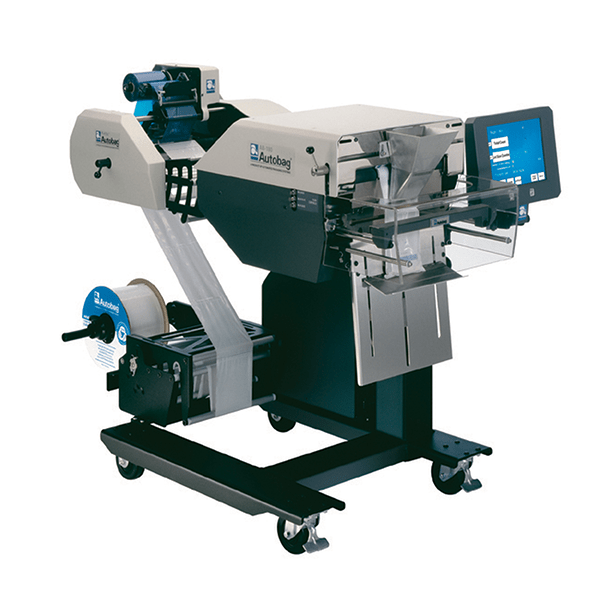

Tailor-made automated packaging systems are customized packaging solutions that are specifically designed to meet the requirements of a particular sector, like industrial, food, cosmetics or pharmaceutical products. These systems optimize the process of packaging and improve the efficiency of production. They also satisfy the specific needs of every sector.

Packaging configurations that can be custom-made- These systems may be customized to meet the specific needs of the industry. This can include the dimensions and shape of the product, in addition to the material and type of the packaging material.

Processes for production that are efficient Custom-designed automated packaging systems increase the efficiency of production and reduce the amount of downtime. They are perfect for production environments with high volumes.

Advanced technology. These systems utilize state of the art technology such as robotics, programmable logic controllers, and advanced sensors to ensure the same, precise operation.

Quality Control- Customized automatic packaging systems are created to ensure the quality of the packaging. They help reduce waste while increasing customer satisfaction.

Cost-effectiveness- These methods can be utilized to cut down on packaging costs while still delivering high quality outcomes.

In the end, custom-made automated packaging systems are able to provide tailored solutions for every industry's unique requirements. This can help optimize the packaging process, increase production efficiency , and decrease overall cost. View the top rated matériau emballage biodégradable for website recommendations.